LR Products Tri-Plex Solvent Adhesive Mixer Dispense Systems: Monitor adhesive coat weight in real time

lr products TRI-PLEX MIXER

TRI-PLEX MIXER ACTIVATES AS FAST AS YOU CAN SAY “GO”

Advantages

Accurate and reliable for Adhesive, Solvent and Activator mix ratio.

Dispense on demand based on consumption.

“On the fly” ratio changes

Mix container with stir system before going to a transfer tank.

Viscosity is checked and modified before transfer to coating unit.

Automatic g/m2 calculations, real time during the production run.

Production control data reports

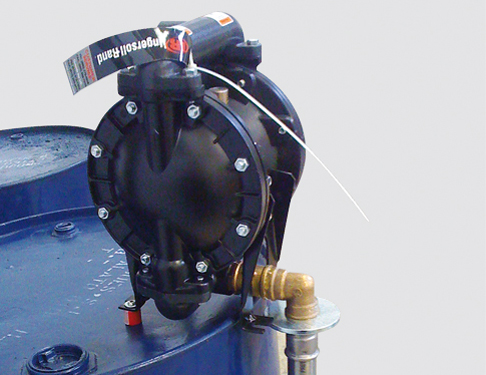

Special pumps regulate the flow of the three components on demand in the recommended ratios.

We monitor the lay down coat weight showing the lbs./ream function, displays a continuous lbs./ream usage of the right amount of adhesive applied to the web. (This is will all our systems)

Ability to monitor the A & B ratio components accurately.

Savings in scrap laminated material due to above.

New Solvent system is unique because we blend the adhesive on demand, because of the short pot live.

lr products BI-2Mixer

DUPLEX MIX ACTIVATES EVERYTHING BUT A BORED TEENAGER

LR PRODUCTS BI-2 MIXER

AUTOMATIC SOLVENTLESS

ADHESIVE MIXER with over 800 sold worldwide

Accurate and reliable

Monitor the A&B component ratio within set limits. Alarm or shut down automatically

“On the fly” ratio changes

Special gear pumps monitor the flow of A&B components

Automatic g/m2 calculations real time.

Temperature monitored at three points.

Production data reports

Maintenance trouble-free

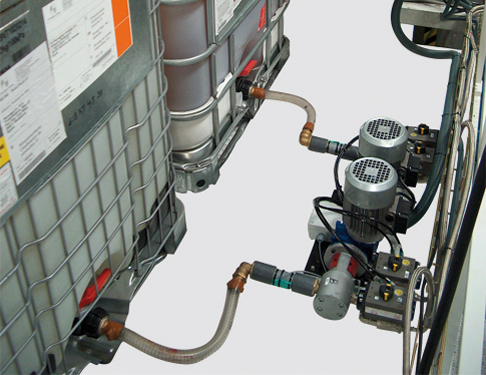

Several automatic refilling options

Duplex Adhesive Meter Mix Dispense Systems: Monitor adhesive coat weight in real time

Multiple configurations available including gravity fed high volume or automatic drum transfer

The bi-2 mixer is the most advanced technical solution for solventless adhesive mixing and metering, enabling the highest level of accuracy and quality for the lamination process.

This is achieved by means of the proven lr.products gear pumping technology, controlled by an industrial electronic PLC platform and a proprietary developed software.

AUTOFILL: OPTIONAL AUTOMATIC REFILLING

Increase productivity, no need to refill the mixer by hand, fully automates a previously tedious process.

It prevents the creation of a jelly skin on the surface of the adhesive because there is no moisture inside the component tank.

The auto-fill works in a completely enclosed environment.

OUTSTANDING FEATURES

Unique in the market: calibration function

The calibration function allows the system to calibrate as a function of the adhesive.

Once done, the unit accurately meters the exact amount of each component in weight ratio.In line g/m2 calculation function

In line g/m2 calculation function

Once calibrated, the PLC makes a continuous calculation for the g/m2.

A graphic display shows the operator any movement away from the desired amount.

INCLUDED FEATURES

High accuracy, easy to use and even easier to install

MAN/AUTO, ‘clean’ and ‘empty tanks’ function

Variable flow according to consumption

Alarms and troubleshooting diagnostics

Reports on consumption, output and g/m2 coating

Optimum temperature of adhesive maintained prior to production

Can be installed in any laminator available in the market

Totally problem free maintenance

Independent temperature selection

Double temperature control for higher security

Permanent level control by means of ultrasonic sensors

Stainless steel construction

User Friendly Equipment

Interchangeable static mixer on the mixing

head

Adhesive mixing and application just at the

metering point

Easy to install at set-up

Stainless steel removable tanks

Tool free, easy to clean and manipulate

lr products BI-2Mixer Mini

BI-2 MINI MIXES EVERYTHING BUT YOUR FAVORITE COCKTAIL

COMPACT

LOW VOLUME SOLVENTLESS

ADHESIVE MIXER AND METERING UNIT FOR LAMINATION

Accurate and reliable

Production control

Automatic g/m2 calculations

“On the fly” ratio changes

Production data reports

Maintenance trouble-free

Several automatic refilling options

Duplex Adhesive Meter Mix Dispense Systems: Monitor adhesive coat weight in real time

Multiple configurations available including gravity feed designs

The bi-2 mixer is the most advanced technical solution for solventless adhesive mixing and metering, enabling the highest level of accuracy and quality for the lamination process.

This is achieved by means of the proven lr.products gear pumping technology, controlled by an industrial electronic PLC platform and a proprietary developed software.

AUTOFILL: OPTIONAL AUTOMATIC REFILLING

Increase productivity, no need to refill the mixer by hand, fully automates a pre- viously tedious process.

It prevents the creation of a jelly skin on the surface of the adhesive because there is no moisture inside the component tank.

The auto-fill works in a completely enclosed environment.

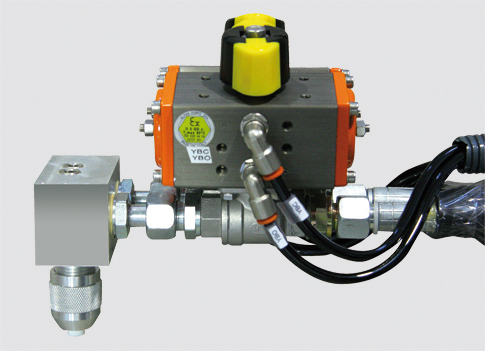

lr products MoDos Mixer

MODOS MIXER: ONE MO THING TO NOT WORRY ABOUT

SINGLE COMPONENT SOLVENTLESS ADHESIVE

eXCELLENT FOR FILM OR FOIL TO PAPER OR PAPERBOAD

MAIN OPERATIONAL ADVANTAGES

The remaining adhesive not used in the drum will not deteriorate.

Possible to interrupt the dosing and the return to dosing.

Not necessary to clean the equipment during shutdowns.

Neither the hose nor the metering pump need cleaning.

Adhesive in the drum is consumed to the maximum, practically without residual waste.

Drums with dents or blows can be used.

Suitable for drums with or without internal plastic bag.

Independent controls for temperature in 4 sectors.

MoDos Mono Adhesive Mixer Dispense Systems: Monitor adhesive coat weight in real time

MINIMAL PROBLEMS OF CLEANINGWITH

LOW MAINTENANCE

The modos-200 equipment is the most advanced technical solution for dispensing mono-component adhesives, providing an easy usable and maintenance free operation which were previously unattainable.

This accuracy is achieved by the well known gear pumping technology developed by lr.products and controlled by an industrial PLC running a specific proprietary software.

The lr.products) experience in gear pump technologies, allows the converting industry to have a simple and excellent equipment, with substantial improvements over any equipment based on a heated piston or a meting plate

Main Operational Advantages

The remaining adhesive not used in the drum will not deteriorate.

Possible to interrupt the dosing and the return to dosing.

Not necessary to clean the equipment during shutdowns.

Neither the hose nor the metering pump need cleaning.

Adhesive in the drum is consumed to the maximum, practically without residual waste.

Drums with dents or blows can be used.

Suitable for drums with or without internal plastic bag.

Independent controls for temperature in 4 sectors.

Outstanding features

Independent temperature control in 4 sectors

Precise adjustment of adhesive temperature

Temperature controls drum, pump, hose and nozzle

Fast heating of adhesive, ~10 minutes

Unique in the market: targeted calibration

Function allows to calibrate unit to actual density of adhesive

Equipment reports exactly the amount of supplied adhesive

Function of online g/m2 calculation

PLC on the equipment calculates continuously the application of g/m2

Touch-screen graph shows eventual deviation from the desired weight